'Bee-R' ITU Formula SAE Car's Mechanical Design

ITU Formula SAE Team, which is Turkey's first Formula SAE Team, was founded in 2006. Our target was to take the initiative to start Formula SAE in Turkey and produce a car for the 2007 Formula SAE Italy event. However, due to the difficulties of making the university's and also the country's first Formula SAE car, the efforts failed to design a producible one. In October 2007, the remaining members of the team, mostly consisting of second-year students and two M.Sc. students, started to work on a new design.

Due to our very small team and bureaucratic procedures, our work slowed. In the spring of 2010, we, as ten students from different engineering branches, completed Turkey's first Formula SAE car. After four years of sustained commitment to complete the project, we entered the Formula SAE Michigan 2010.

In this project, as we were only a few members, I (and also the other members) worked on almost the entire mechanical design. However, the chassis and suspension design were my primary responsibility.

After attending Formula SAE Michigan 2010, we as the designers of the first car founded a completely new team for the design and production of a new F-SAE car for future events. We also left the team leadership to a freshman student in order to establish continuity in the new team while providing them with experience and knowledge. Although we as the founding members are not in the team anymore, we all try to mentor the team in fields where guidance is needed.

More information about the ITU Formula SAE Team can be found on the team's web page.

MEKAR Grand Cooperative Driving Challenge Vehicle's Automatic Brake & Gas System Design

The Grand Cooperative Driving Challenge (GCDC) is an international challenge that aims to accelerate the development of cooperative driving technologies. Cooperative driving aims to form platoons of vehicles on the roadways by having the cars communicate with each other and with the infrastructure. By transmitting the vehicle's state information to the vehicles behind it, the vehicles inside a platoon will be able to brake and accelerate simultaneously. The eliminated human reaction times will allow closer headway between vehicles, thereby reducing it significantly. Hence, with the use of Cooperative Adaptive Cruise Control (CACC), more efficient use of existing infrastructure alleviating traffic problems and reduced fuel consumption will be achieved.

The GCDC is held by TNO in the Netherlands on the 14th and 15th of May 2011. Team MEKAR challenged its rivals with its half-autonomous car and placed 7th overall and 5th in the individual category. It was a good rank for us as we did not have any autonomous or semi-autonomous vehicles which we could easily equip with the necessary hardware and software required for the C-ACC. The vehicle we had developed was not fitted with an OEM Adaptive Cruise Control (ACC), so we also had to deal with incorporating ACC into the vehicle, which most of the other teams had as standard equipment on their vehicles. Our vehicle was intrinsically sluggish due to its heavy weight, exceeding 1700kg with the equipment installed, compared with the IC engine power of 90 hp (67kW). Besides the low hp/1000kg ratio, the delays during the shifting were also relatively high due to the tiptronic shift, which made our vehicle even slower. More information about our MEKAR GCDC Vehicle can be found in the IEEE Transactions on ITS GCDC Special Issue.

Team Mekar's GCDC vehicle is a Fiat Linea sedan provided by our major automotive OEM sponsor Tofaş-Fiat for use during the race. Istanbul Okan University, Istanbul Technical University, and OTAM (Automotive Technologies Research and Development Center) were our main sponsors for the GCDC event. I was responsible for designing a closed-loop control system needed for braking and accelerating purposes by forming the necessary longitudinal vehicle model, and the mechanical design needed for sensor, actuator etc. mountings. Mechanical design had a constraint that we had to make the changes on the car without drilling any holes or making any weldments. I was the only undergraduate student in this project, and my senior design project covered controller integration by using a rapid controller prototyper (we were using Microautobox) and performing road tests.

Online Estimation of Driving Resistance Parameters

I took part as a student researcher in a research project between Dr.-Ing. h.c. F. Porsche AG and KIT - Institute of Vehicle System Technology. The goal of this project was to estimate the unknown driving resistance parameters by the use of online filters.

My advisor in this project, Dr.-Ing. Stephan Rhode, was researching online filters and performed test-runs to investigate the quality of the developed vehicle models. Data acquired from the vehicle CAN-Bus thereby allowed accurate range prediction and better driving strategy selection.

In this project, I provided assistance to my advisor in post-processing for roughly four months. My duties included creating codes in MATLAB for various filter types, plotting figures which could serve for ease of model selection, improving the visualization of figures, and literature review about the topic.

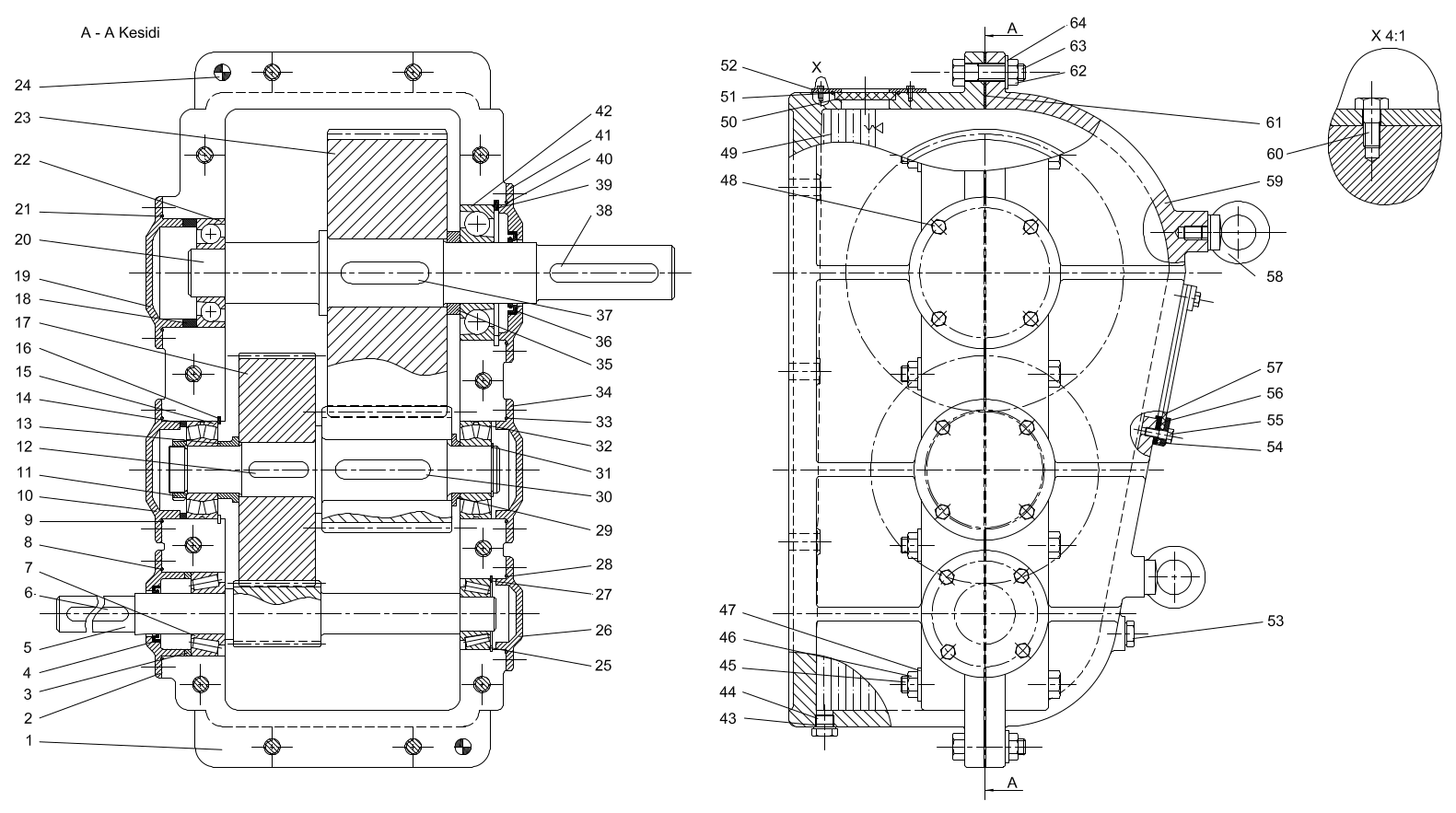

Gearbox and Coupling Design

As a mechanical engineering student, I had to design some gearboxes, shafts, HVAC-systems etc. Interested readers can access the designs of some from the links below:

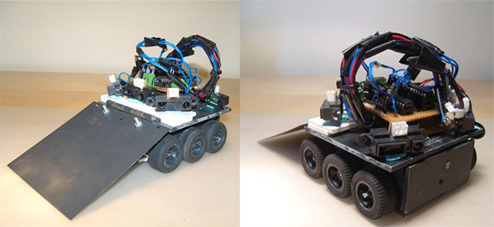

'HaydARI' Minisumo Robot Design

A sumo robot's task is to push the robot that it is competing with to outside a circle. Mini-sumo robot is a subcategory of sumo robots. They can be up to 500 grams and 10 cm by 10 cm without any height limit. Sumo robot competitions are held worldwide with Japan being the pioneer. I had prepared a mini-sumo robot for METU Robotic Days in 2007. Because it was my first robot with which I took part in a competition, it has a special place for me.

To determine the position of the opponent robot, five Sharp 2D150A F IR sensors were used, with there of them looking forward. The necessary algorithms were written on ANSI C and were implemented on a PIC16F628 microcontroller. To overcome the 10 cm x 10 cm restriction, the robot was designed to expand after the start by opening its front plate.